The company

About our company

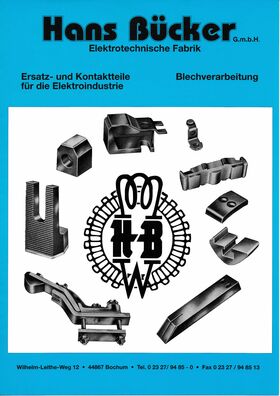

Our company was founded in 1948 and specialises in the manufacture of contact material for the electrical industry.

- Manufacture on CNC machines and conventional machinery.

- Manufacture of samples, manufacture in small lot sizes and in series production.

- Preparation of quotations according to drawing, sketch or sample.

- Short delivery times and special designs are possible upon agreement.

- Tin-plating, nickel-plating, galvanising and silver-plating in our own electroplating shop.

- Reconditioning of old contacts and copper bars.

- Certified environment and quality management system.

We are manufacturers of contacts for contactors, elevators, fork-lift trucks, cranes, etc. for all types of products. Special designs and the manufacture of samples are possible upon agreement. We manufacture according to your specifications (drawing, sketch or sample).

There is no need for scrapping your old contacts. We regenerate them with new silver coatings and silver platings in our in-house electroplating shop where we also perform operations such as nickel-plating, tin-plating and galvanising.

Copper or steel plates with a maximum size of 650 x 1000mm are processed on our CNC punching machine.

We provide flat and round copper in commercially customary sizes with bores, threads, bends, bushes, etc.

Flexible current leads and expansion connectors made of copper foil are riveted or wound.

Copper solder tags are welded and tin-plated.

For the manufacture of insulating parts, we use various types of plastic materials (for example HM2472 and Makralon) which are available in sheets or rods.

We manufacture punched parts and sheet metal parts made of copper or steel up to 6mm thickness. Straps, clamps, connectors – bent, soldered, welded. Special designs can be supplied thanks to our own tool manufacturing capabilities.

Special sizes are available upon request.

Test our reliability and flexibility.